LinMot overview

|

Industrial Linear Motors LinMot

LinMot linear motors are direct electromagnetic drives. The linear motion is generated without wear, with no intermediary mechanical gearboxes, spindles, or belts. The motor is made up of just two parts: the slider and the stator. The slider is made of neodymium magnets, which are mounted in a high-precision stainless steel tube. The stator contains the motor windings, slider bearings, position sensors, temperature monitoring, and microprocessor circuitry with an integrated electronic nameplate. LinMot's standard catalog includes 13 different families of motors with peak forces of between 33 and 1024 N. All models are available with different stroke lengths and features over 400 different linear motors altogether. LinMot linear motors and servocontrollers are built for use in harsh, demanding industrial environments. Their exceptional technical properties, low-maintenance operation, and extremely long life set them apart. Flexible LinMot linear motors can be positioned freely along their entire stroke. Travel speed and acceleration can also be precisely defined. For more complex motions, any number of motion profiles can be stored in the servo controller as curves, and the motor can execute the motion at the desired speed. The motion of the linear motor can also be synchronized with another rotary or linear motion. |

| Dynamic and Precise Extremely dynamic motions can be achieved with industrial linear motors. Speeds of up to 5,5 m/s and accelerations of well over 300 m/s2 provide very short positioning times and high cycle rates. With the elimination of components afflicted by mechanical play, such as gearboxes or gear racks, linear motors can be positioned as precisely as desired, consistent with the resolution of the measurement system. Reliable The internal position sensors measure and monitor the current position of the linear motor, both at rest and in motion. Deviations from desired position are captured immediately and reported to the control system. This guarantees a high level of operational security and reliable error detection. And, since there are no wearing components, such as gearboxes or spindles for power transmission, even extremely dynamic motions can be achieved with a long operational life. |

|

|

LinMot Design Element

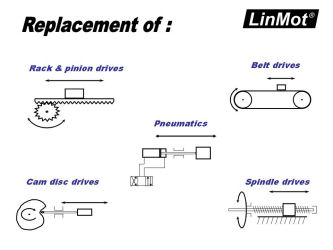

LinMot industrial linear motors are a design element that offer significant advantages over typical elements such as pneumatic cylinders, servomotors with spindles and belts, or mechanical solutions such as cam, discs or crank designs. LinMot industrial linear motors are a new design element that enables innovative solutions for completely new functional units, modules, or entire machines that were previously impractical using traditional elements. The high level of integration (bearings and position sensors are integrated in the motor) and the ability to integrate LinMot systems into a wide range of control systems shorten the design-in time. LinMot Fields of Application LinMot linear motors and servo controllers are built for use in harsh, demanding industrial environments. Their exceptional technical properties, low-maintenance operation, and extremely long life set them apart. The enclosed design, with all motor components encased in a solid steel tube, as well as integrated magnetic field position sensors, allow reliable operation even in dirty or wet environments (IP67). Within the wide Product range, electrical products for complex Servo application and simple pneumatic replacement are available. All of these properties make linear motors the ideal solution for linear motions in packaging machines, material handling, textile machines, medical equipment, custom machines, and many other applications. |

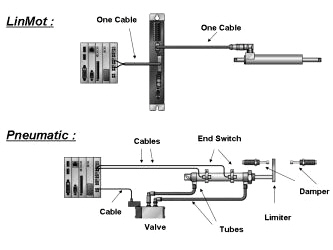

| Replacement for Pneumatics Since the form factor of LinMot linear motors is similar to that of pneumatic cylinders, they are often used are replacements for pneumatic cylinders. This is especially the case when more than two positions are required, if the positions need to be changed via software, or if the dynamics or lifespan of the pneumatic cylinder are not sufficient. The linear motor also provides the ability to define the speed and acceleration precisely, which makes start-up easier and increases process stability. Replacement for Servomotors Linear motors have comparable capabilities and flexibility of rotary servomotors. The advantages of linear motors are clearly overwhelming, since mechanical accessories such as couplings, gearboxes, belts, spindles, and the extensive design work that they require, can be completely eliminated. The design-in time and logistical burden are significantly reduced by the elimination of this array of mechanical components. Replacement for Cam Discs Mechanical cams allow extremely dynamic motions, but leave much to be desired when it comes to flexibility. Motion profiles can be changed only by extensive mechanical rework. The very high dynamic capabilities of industrial linear motors, plus the ability to adapt motion profiles in software, have led to the replacement of more and more mechanical cams with LinMot linear motors. For more information about LinMot Industrial Linear Motors, see "General Data Book V15.pdf", here. |

|

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)